Prototype castings in metal

Prototype castings in metal

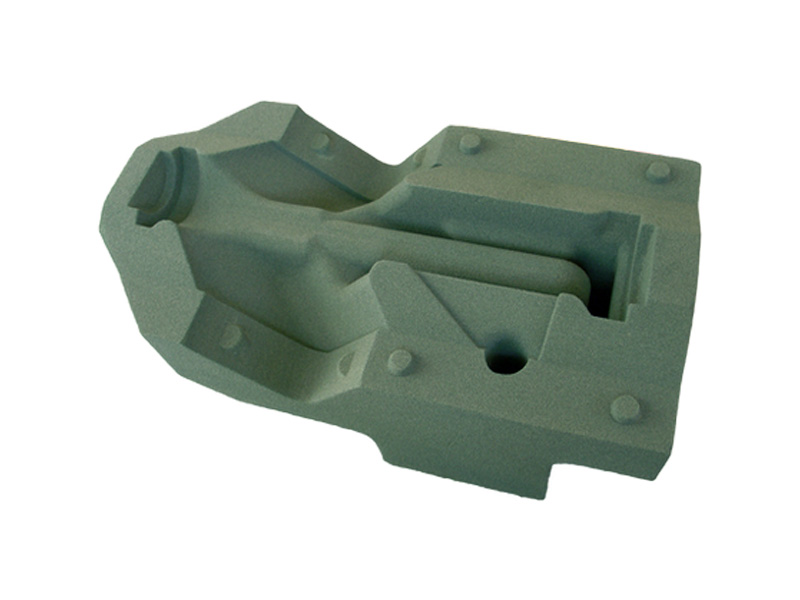

We create prototypes thanks to 3D polymerization forming machines, similar to those for the laser sintering of Nylon, with which it is possible to produce complex elements in polymerized refractory material. These elements are used as disposable molds for the production of even very complex castings (cavities and undercuts) in the following materials: Gray Cast Iron – Spheroidal Cast Iron – Bronze – Brass – Aluminum

The whole can be used for castings of considerable size and weight (even greater than one meter of development and 50 kg of weight).

The granular refractory is processed layer by layer, in analogy to what is known for the laser sintering of Nylon powders, but the cohesion of the individual grains is obtained by cold polymerization (with catalyst) which produces parts that are not deformed or tensioned and can be directly assembled in a complete mold that can be used in foundries.

This technique therefore allows to obtain functional prototypes similar to final production products, with the addition of the simulation of the casting process and the identification of particular defects related to sub-thicknesses that other prototyping techniques do not verify.

The average production times are 9-14 working days from the 3D file to the final casting, and may vary according to the number of details required and their size.

Materials:

Gray Cast Iron – Spheroidal Cast Iron – Bronze – Brass – Aluminum

Maximum size:

Cast iron: 100 kg

Aluminum: 35 Kg

Time of realization:

9 – 14 working days

File for the realization:

3D file with oversizes or 3D file finished piece

Investment casting or lost wax casting

The investment casting or lost wax casting, uses identical models in the geometries to the piece to be produced in metal. These models commonly called waxes, are made of special materials that are designed to liquefy or burn at relatively low temperatures without leaving ashes or residues. Sacrificial waxes or patterns are used to make a structure known as a cluster. This wax structure is embedded in an inert material (plaster or liquid ceramic) and then fired. During firing, the refractory solidifies and the waxes dissolve, leaving a cavity identical to the piece to be made. With the casting system it can therefore be filled with aluminum (if the shell is in plaster) or with steel (if the shell is in ceramic). The ceramic shell is considerably more resistant but a very long process is required to create it. The sacrificial model is immersed in the liquid ceramic, allowing a thin layer of ceramic to dry and harden. This operation is repeated many times.

The “ceramic” investment castings are characterized by a very high resolution up to ± 0.05mm but precisely because of the very high number of layers that are used to build the pieces, the details with dimensions above 120 mm in height tend to have very high costs , with maximum dimensions up to 350 mm.

Materials:

Castings in aluminum alloy (GAlSi10 – A 357)

Precision castings in steel (C40 – AISI 304 – AISI 316)

Dimensions:

up to 350 mm

Time of realization:

about 11 – 12 working days